Nasza firma to doświadczony producent o ugruntowanej pozycji na rynku, który specjalizuje się w produkcji i montażu wyrobów o wysokim stopniu skomplikowania.

Most injection molds are made in external, specialized tool shops, which are subject to our continuous control and verification based on quality, timeliness and costs.

METCHEM takes full responsibility for the construction of tools from verification of the correctness of the construction to approval of the final product.

We know that each project is different and requires an individual approach. That is why we offer our Customers a complete and dedicated service, ensuring that each project is tailored to their specific needs.

We specialize in the production and assembly of products with a high level of complexity and the highest level of quality.

We process thermoplastics, mainly technical, both unreinforced and reinforced with various types of fillers.

In production we use construction materials, e.g. PA, PP, POM, PBT, PC, PMMA, ABS, ASA, including high-temperature technical plastics, difficult to process like PPA.

We constantly strive to perfection and optimize production on a basis of feedback analysis from digital production management systems.

Our main directions of production are:

injection of thermoplastics

manual, semi-automatic and automatic assembly

ultrasonic welding

foam and filter punching

Depending on availability, we provide services:

electro drilling

laser welding

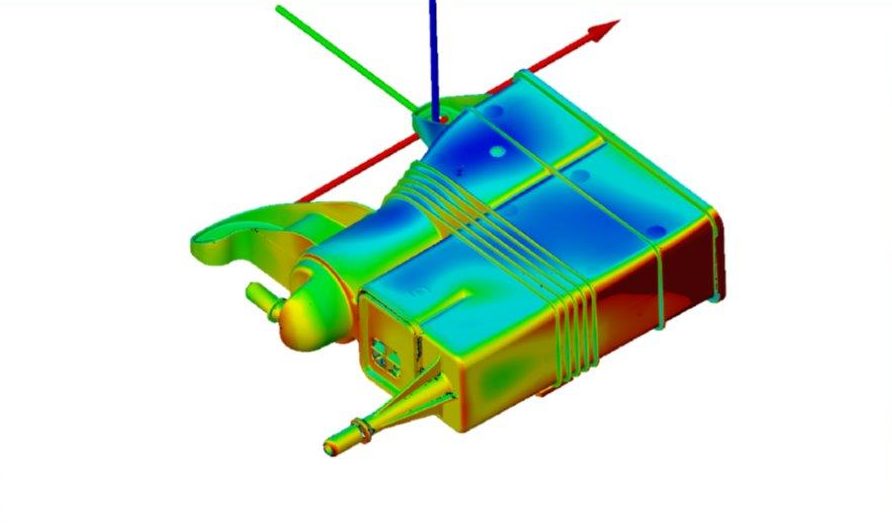

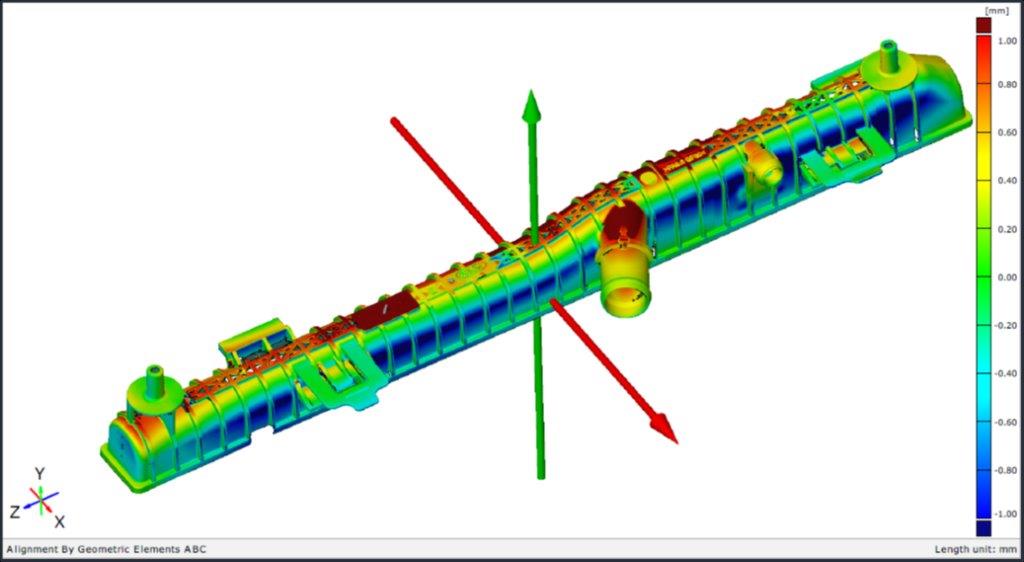

measurements with a spatial optical 3D scanner

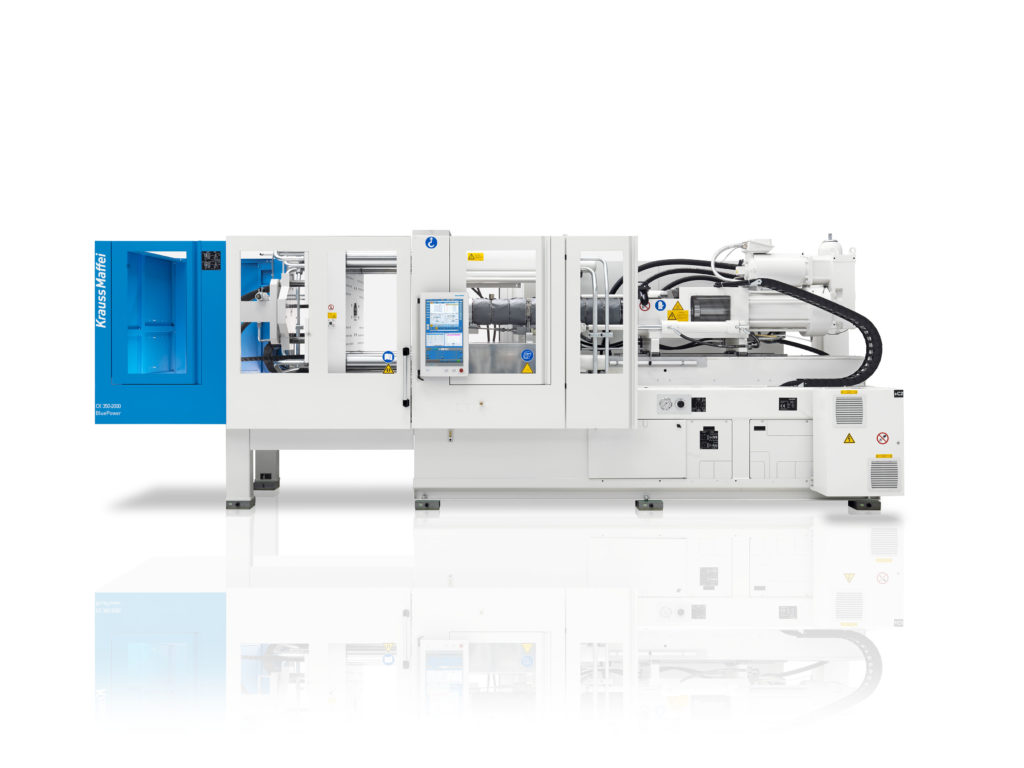

Having an advanced machine park of top-class injection molding machines, which we constantly modernize, we can provide our Customers the highest quality of manufactured products and just in time realization of orders.

We have machines with a clamping force of 50-1100 tons with 3 and 6-axis robots.

We produce details weighing from several to 4500 grams.

We use the highest quality materials and tools to ensure that each product meets the expectations of our Customers.

We constantly strive for perfection and optimize production based on feedback analysis from digital production management systems.

We carry out maintenance activities aimed at ensuring production continuity and eliminating unplanned downtime.

Current maintenance, inspections and repairs of injection molds are carried out in our tool shop. We have our own tooling facilities to effectively and efficiently service and repair injection molds and tooling.

The tool shop is equipped with e.g. lathes, milling machines, grinders, as well as an EDM machine and a laser welding machine.

In addition, we closely cooperate with tool shops in Poland and abroad, shortening the repair time and eliminating possible downtime caused by failures.

The quality of our products is extremely important. Following the continuous optimization of production processes, we make sure to develop our capabilities in measurement and data analysis in a similar way.

Our quality engineers have knowledge in measurement methods supported by many years of experience, and our laboratory is equipped with the highest-class measuring equipment ensuring the possibility of all types of measurements (we have e.g. two Zeiss machines, a GOM optical scanner, a KEYENCE profilometer and an optical measuring projector).

At METCHEM we know that proper storage of materials and finished products is crucial for their quality. That is why we store them in a modern warehouse with monitored temperature and humidity, with an area of 2.700 m2, a height of over 11 meters and a volume of almost 30,000 m3, located directly at our plant. We have a total of 3.565 pallet places at our disposal.

High-storage racks ensure optimal use of warehouse space, and flow racks and our ERP system easily allow to control the correctness of the rotation of goods using the FIFO method.